Week 8 now, not counting spring break. This puts us at halfway through the semester. I feel like time has really slowed down now.

Updates

While I usually don’t talk about my personal life in these since it isn’t relevant to the project, I have a few things to bring up from spring break.

First of all, if anyone out there is looking to upgrade or build a new computer, I recommend not buying Nvidia GPU’s unless you have a really good deal on the high-end cards. Nvidia cards have been becoming increasingly overpriced compared to their competition, and their design choices baffle me. I had the cable for the 3090ti break on me because it’s been getting squished in every computer case I’ve had because the 3090ti is already so wide, and the cable just barely fits. And now AMD is producing the 9700xt which has amazing value for its performance.

Amazon also failed to deliver the replacement cable to my address, causing me to hunt it down the entire weekend despite getting overnight shipping, because the replacement wouldn’t arrive until today. Because my computer was out of commission, I ended up playing more of Armored Core 4 on the PlayStation 3, which has been really fun (after I got good at the game).

But besides that, there is one other package that arrived over the break that I have been beyond excited to talk about:

I managed to get my hands on the only Jaller store display I was able to find on the internet. It took some negotiating, some DoorDashing, and a bit of lucky patience, but it is finally in my hands at long last. This means I can now finally figure out how Lego wired up these swords.

The display, despite being in a bit of a broken state, poor Jaller, still lights up even brighter than some of my swords with new batteries in them. Despite my initial assumptions, it uses the same flashing feature as on a normal sword rather than a slow fade in and out, which already tells me that they still use the circuit board in the sword, so I worry that it will just be another case of soldering on to the custom board.

Nevertheless, let’s crack this open and find out for sure.

In The Flesh

Full disclosure, I had already opened this up just beforehand just to make sure I knew how, so the screws are easy to remove now, but they previously required some force.

Taking off the lid, the underside reveals that the button is connected to cables that plug into a cable connector, absolute shocker.

Beyond that, the cable that this connector plugs into runs behind the paper background, but I’m uncertain how to remove it currently (which I will have to figure out to be able to repair Jaller’s head).

Something I’d like to point out is the sheer amount of glue that is on this display. Every single joint, pin, pin hole, axle, axle hole, and even each Zamor sphere are absolutely encased in this stuff, almost to a comedic degree.

As Cartland said, “They really didn’t want this going anywhere!”, which definitely checks out. Between the PET-G plastic casing, the glue everywhere, and the security ties around Jaller’s waist and neck, I have to imagine it wouldn’t even budge even if a kid threw it on the ground and jumped on it like a trampoline.

At least in 2006 anyway. It seems that joints are commonly broken on these displays today, from everything I have seen online. No matter though, this display is safe in my hands now and I will do my best to treat it with the respect it deserves.

I already went through the process of purchasing some replacement parts for both the currently broken joints, and for any other joints that may break during this process. But before tearing any of it off, I would like to find out what type of glue is used on these so that I can find something similar for the replacement.

The glue is oddly springy, transparent, rubbery, and it looks like it flowed very well with how precise some of it fits over these parts. Still though, everyone I have asked so far hasn’t had any clue what it could be. I have a feeling Michael will know though.

Continuing the dismantling process to reach the sword, I took off the bottom cap thinking that it would let me take the plastic barrier around Jaller, but unfortunately, I was wrong.

Jaller, the background, and the plastic are all connected together somehow. I’m still mostly uncertain how, so I continued to take apart what I could.

There are a few things on the back side worth mentioning. First is the clamp that was used to attach the display to store shelves, which is screwed in with a massive flathead screw. Furthermore, there is also two small Philips screws, and what seems to be the security band around Jaller’s waist wrapped around two bolts screwed on by nuts.

I decided to remove the smaller screws first, which, besides making me realize how sharp they were (and putting a few tiny holes in my skin), did a lot of nothing, so I opted to remove the nuts next.

I untied the security cable, which made me a little uncomfortable, but not too worried since it’s the same type of cable used for bread bags. From there, it was as simple as unscrewing the nuts with a wrench. Unfortunately, this also led to nothing.

So I decided to try removing the clamp, thinking that it was hiding some other screws behind it. I was able to take off the bottom part just by turning the screw on the bottom, which loosened a nut that was hidden on the top part.

Doing this… also revealed nothing new. I wasn’t really sure where to go from here, so I just tried prying off what I could.

The transparent white piece, that the initial two nuts kept in place, moved a bit but didn’t come off. Although, it does look like it is a separate tube and cap piece, so maybe with some more force it may be persuaded to come apart.

Before trying that though, I tried to see if the entire black strip would budge at all. While it did move in the corners, it does seem the piece is glued on, which makes me hesitant to remove without knowing how I’ll be able to put it back together. I’ll see what Michael has to say regarding this.

It looked like my only option was to try taking off the white block from earlier, so I got to work. By twisting and turning while gently holding Jaller and pulling it, it did come out, but not in the way I was hoping.

Instead of just the cap coming off, the entire tube came out. I’m assuming this is going to make it more difficult to put it back in later.

But with it out of the way, Jaller is now much looser, but still held down by the wiring. The wiring goes behind the Inika background, to a space between it and the black strip on the back, so I have no way of taking it out without removing the glue.

Since I won’t have a chance to talk with Michael until tomorrow, and it’ll be even longer until I get the replacement glue, I decided to just try and wrestle Jaller out of the case as best as I can, and open the battery cover from there.

I removed the cable around his waist and pulled his broken neck socket through the cable around it, but I still couldn’t get him out of the case, until I spotted a rather well hidden cable wrapping the wires around his arm.

It was a bit of a pain to get untied at first since I couldn’t find the point where it stuck out, but after some prodding with tweezers, I was able to get it untied and pull Jaller out of the case.

Thankfully, there was no glue on the battery cover screws, so they came out incredibly easily.

At long last, I’m able to pull it off and finally discover how it was done by Lego, and…

It’s… nothing special at all?

It’s literally just the normal component that’s in every standard Inika? That’s it?

I mean, I suppose my guess was correct, but I was really hoping I would be wrong. Learning this discovery has dampened my spirits quite a bit. It’s starting to seem like the best option, or maybe even the only option, will be to solder my cables together. I’ll have to brainstorm incredibly hard to figure out a solution.

But, with this discovery made, I have no more use in tearing this display apart anymore. I’ll work on fixing up Jaller as a side project and keep the progress chronicled on here, but other than noting what glue is used I’m guessing that’s about all there is to this display. Although it will still serve as a good inspiration of what I want my display to look like.

While reassembling the case, I first forgot to put the battery cover back on to the sword, and then had a lot of trouble with the two nuts on the back of the case. I discovered that they were actually attached to Philips-head screws behind the paper background, and I wasn’t able to tighten the nuts back on because the screws became loose. So, I unfortunately had to damage the paper a little bit to fit a screwdriver in and allow me to tighten the nuts on.

Thankfully, the damage is mostly hidden behind Jaller, but I absolutely want to avoid something like this in the future if I can help it.

Besides that, I didn’t have any trouble putting the transparent rod back in, which was good, and the rest of the case was just as easy to put back together as it was to take apart. I’m still not sure what those two smaller screws on the back were used for; they didn’t affect anything coming out, and they screwed back in without any issues, so I know they weren’t just keeping the paper background flattened, or something.

As I said before, I’ll work on repairing this as a side project, and it’ll still be useful to have for references, but I’m still a bit devastated that I wasn’t able to find any more clues on how to tackle the wiring.

Back to the Start

While I was working with the display case, I tried coming up with solutions to my wiring problem, and I did come up with something. I don’t believe it’s a good something, but it’s better than nothing.

Every time I’ve dug around the electronic part boxes in the DKC, there’s been one cable that has caught my eye:

This oddly short cable connector. I’ve seen some that look similar to it, pictured on either side of the connector below, but I’ve been unable to find any similar connector that is as short as it.

I wasn’t really sure how to look it up, so I asked ChatGPT about it.

The AI told me that it’s most likely a modified version of the cable connectors seen above. This would explain why I can’t find one of these length’s out of the box, and why it also has tape, or perhaps a shrink-wrap, around the cables.

With this knowledge, I attempted to try making a modification myself. I took two of the single wire connectors (because I couldn’t find any of the 2 pin ones), wrapped them together in electrical tape, and then just tried cutting them in half with cutting pliers. I then wrapped the cut point in more electrical tape, and was left with this:

It’s not the best, and the terminals inside the plastic housing are trying to fall out, but it should technically work.

I tried to fit it into Matoro’s test sword, but unfortunately the design is still too long, and the tape isn’t flexible enough to fit in, but I also can’t remove any more of the housing or tape since the metal terminals will fall out, so this design does not work.

It seems my best option is to just use one of the basic white 2 pin connectors commonly seen on Amazon, so that’s what I’ll have Cartland buy.

Doing the same thing over and over…

While I await the arrival of the cable connectors, I opted to continue refining the prototype I have now.

I took the only available cable connector here and modified my LED block until it fit properly, giving me this result:

I also switched out the yellow LED that was previously in it to a blue one to match Matoro’s sword. While it looks similar to when it had the yellow LED, there are two key changes.

First, I removed a section of the leg splitting bar in the middle. I found that it was incredibly difficult to remove the yellow LED and then insert the blue one because of the bar, plus it also limited the agility of the legs which wasn’t ideal. Going forward, I will incorporate this change into the initial design of the block.

And second, I removed an extra corner by the wires. This was because while trying to fit it into Matoro’s sword, the cables needed a bit of extra space to be flexible enough to bend the way I needed them to. I won’t be able to apply this change to the base model though, since the side the cables run through will change depending on the position of the Toa’s sword. Whatever way will hide the cables the most is the way I’ll orient them.

I also plan to add a proper lid to this design as well. While removing the leg splitter allows the legs to move more freely, it also causes the LED to fall out fairly easily. Adding a lid would solve this problem with no hassle. For the lid, all I need is a 1mm thick plate in the shape of the bottom of the block, with some pins to keep it locked in place, just like the original design.

I printed the design a couple of times and messed around with it, but unfortunately I discovered a few flaws. First, the pins on the LED block itself made the whole thing awkward to print, and no matter which way I did it, the pins never came out round enough to fit into the lid. And the lid itself was too weak, snapping open each time I tried fitting it onto the LED block pins. I also generally struggled to keep the wires contained within the block and sword compartment.

I’m not sure if increasing the internal density of both the block and lid would help, or if I just need to make the pins bigger, but regardless I wanted to take a break from it while I wait for the rest of the cable connectors to arrive.

Back to Base-ics

I wanted to focus again on the base of the display, since I felt a little worried about how little progress I’ve made on it.

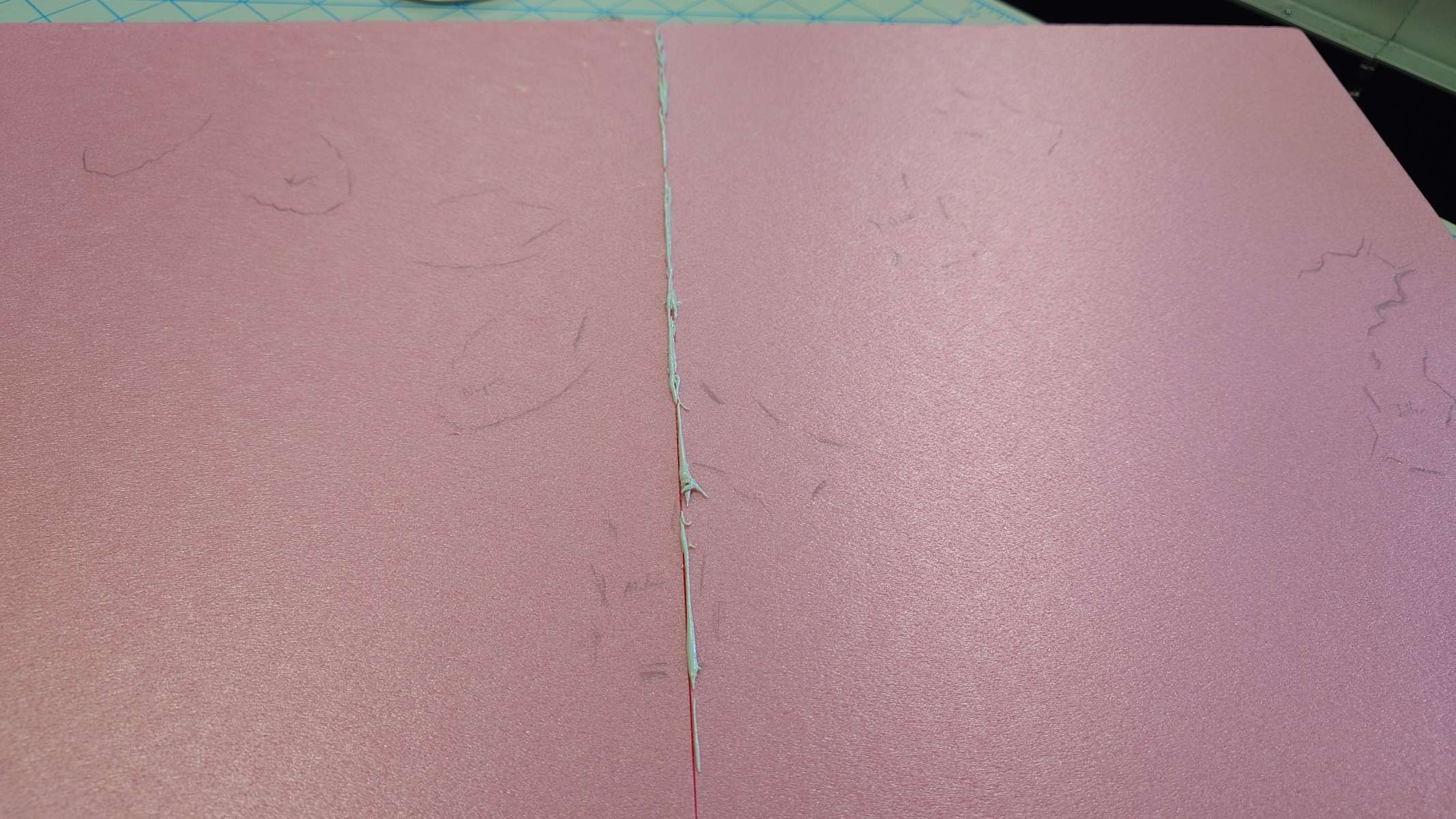

I did some painting on a separate piece of XPS foam again just to get more practice with the actual colors, now that I’m more confident in what I need to do for it.

On the underside of the test piece of XPS foam, I coated it in a mixture of Mod Podge and black acrylic paint, painting two layers on it, to act as a primer. It dried super quickly, giving a pretty satisfying result.

There are a few bumps along the surface that I want to avoid when creating the final product, but I’m not entirely sure what’s causing them. My current guess is that it’s just the brush that I’m using. I’ll probably try cleaning it out as thoroughly as I can and hope it helps.

But, continuing onward, I painted a layer of gray over the primer mixture. While the idea I have in mind is to have a metal-like floor, and the gray I’m using is matte, I’m assuming adding a semi-glossy paint varnish will help achieve the look. If not, then I’ll have to order specifically a silver color paint.

While waiting for this layer to dry, I began printing the bolt and nut idea I had from awhile back, so that I can hopefully ground the Toa without worry. As much as I’d like to use the same technique from the Jaller display case, it unfortunately won’t work too well in my larger case.

Results

The first thing I noticed after it came out was that it’s just a tiny bit small.

The screw does fit within a pin hole, so that unfortunately means I can’t really make this design much bigger, and because of its size, there’s a lot of imperfections on the bolt so that it won’t screw into the block without a lot more effort.

As I was fiddling around with it though, I suddenly realized I’m just trying to do the exact same thing as seen on Jaller’s display, just with a different looking nut. So, I went digging for some nuts and bolts.

I also grabbed some basic screws just to see how they would work, and tried them first with Matoro.

Which worked surprisingly well. I’m still a little worried about the long-term stability of this solution, but I’m thinking that I can place a block of wood, or something of similar material, underneath the foam for the nails to dig into. I’ll only do that if I feel like I really need to though, as getting nails of appropriate length, along with specific sizes of some material to screw into will be annoying to deal with.

But regardless, I did the same with Nuparu just to try the method with his feet. While the pins in his feet are a bit more troublesome to access, the technique works just as well.

This now means we have a solution for both the anchoring problem and the wiring problem. The only thing left to do is practice hiding the wiring around the Toa and running it through the foam to connect to the Arduino board. One I’m confident in doing so, I’ll be ready to start putting this thing together.

And since I can’t move forward without those cable connectors, this will be a good stopping point for the week. I really feel like I’m heading towards a conclusion with this project, even if there’s still so much left to do.

I’m still incredibly worried about the Plexiglass casing, and I can’t even say “I’ll worry about it when the time comes” because that time is coming up very soon. I imagine I will be dealing with it in no more than three weeks. And beyond that, there’s still the issue of the printed graphics and such, which will come up just as fast as the Plexiglass.

But there’s nothing I can do about it right now except get some rest and prepare for the upcoming challenge.