Hey guys, this post will be the last one regarding my project. Before I start anything else, I’m extremely grateful for the DKC allowing me to do this. The experience as a whole was something I highly recommend to anyone looking to get into science or design. It teaches you how to manage your time effectively, meet deadlines, work as part of a team, and manage a large-scale project. I know I have said it before, but the biggest takeaway for me was learning what progress in science is about. Growth is non-linear on these projects, and that is the unfortunate truth about science. There would be weeks of very stagnant growth, and then all of the sudden there would be profound progress, and that really is the beauty of one of these Fellowships is that it prepared me for that in science. Another important takeaway is there will always be something to do that will benefit the long-term well being of your project. Regardless of where the physical construction piece of the project was, there was always something I could do on my computer, or with the supporting pieces of my project. Anyways, I will be outlining the finishing touches of my project in this post.

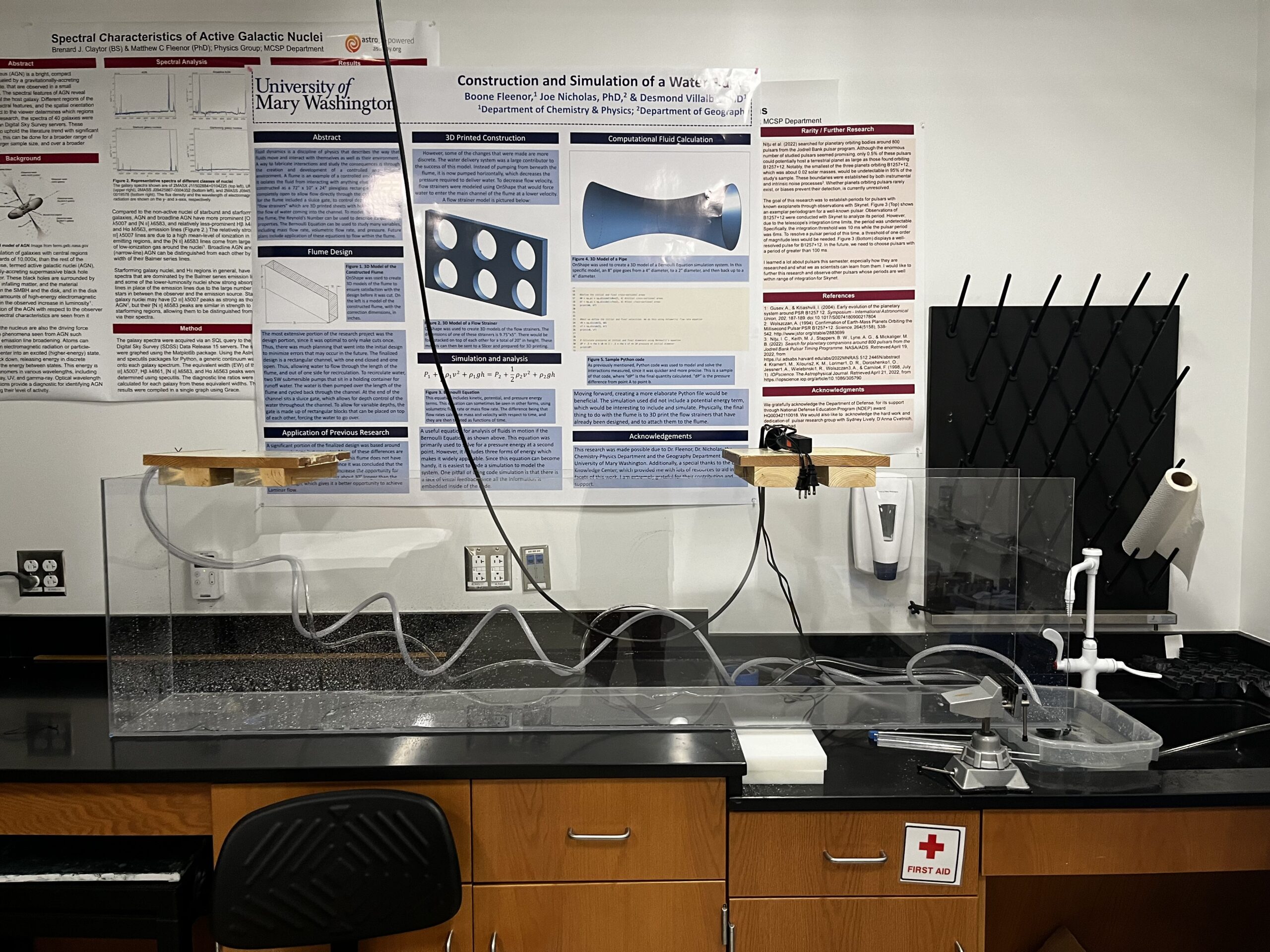

The biggest obstacle right now is that one of our 3D printers I broken, which was an unforeseen obstacle. So, I haven’t been able to print out some of the smaller things. But, all we have left to do is create the gates that will give the flume some depth, and then we will be done! This includes the gates on the end, as well as the front. I will include some photos of the flume in its current state. In the future, Summer maybe, I will be able to create another post of the final-final project. However, the flume is finally complete. Thanks again for everyone who supported and followed me in this journey.