I first wanted to say thanks to those who have taken time to read the blog, and I hope you learned a a thing or two. This will be my last 3D molecular representations blog post and in it I will go over some of my final thoughts and show off all that I have learned.

Brief Overview of Accomplishments…

The CAD side of things…

Three months ago, I started this project by learning how to use CAD software, Fusion360, to edit STL files of 3D molecular structures that were provided by the Protein Data Bank (PDB). Through this time, I learned how to use many of the more basic tools in Fusion360 such as sketch, extrude, fillet, chamfer, split face, combine, inspect, combine mesh, tesselate, and plane cut. These tools were all I needed to make the necessary edits in creating 3D molecular models. I have a more in-depth explanation for most of these tools linked so check them out if you are interested.

The 3D-Printing side of things…

The 3D-printing side of things was a more complicated matter as there seemed to be a sort of “guaranteed chance of error” with the MMU 3D-Printer. In the beginning I was making no progress because the “Wipe Tower” would not be enabled if a particular extruder was set to only be utilized for supports. After figuring out how to work around this issue another problem arose with the soluble filament. The problem here was that the PVA filament I used would constantly clog and sometimes caused a glitch where the MMU would load and unload the filament endlessly. The work around for this was simply using a different soluble filament called BVOH filament. Even with all this there were still issues that I ultimately could not completely avoid such as clogging, simple errors, and filament expiring or going bad from too much exposure to moisture. However, I did find using a filament drier was very useful in keeping filaments in good condition for longer. That idea was from Shannon and Cartland so thanks for that one!

Final Model Montage and Final Thoughts…

Here is a picture of the new and improved BCR-ABL model without all the printing errors from before. Now, I want mention that before I talked about “oh you can show different subunits using different colors.” I just want to say I thought using two colors here would look cool and I wanted to figure out the MMU printer and it does not represent multiple subunits in this case. Also, thanks to Dr. Agrawal for choosing these colors (they look like a gender reveal but otherwise its nice).

Altogether

Apart

Video of the assembly (not including the simulated imatinib or ATP).

Final Thoughts…

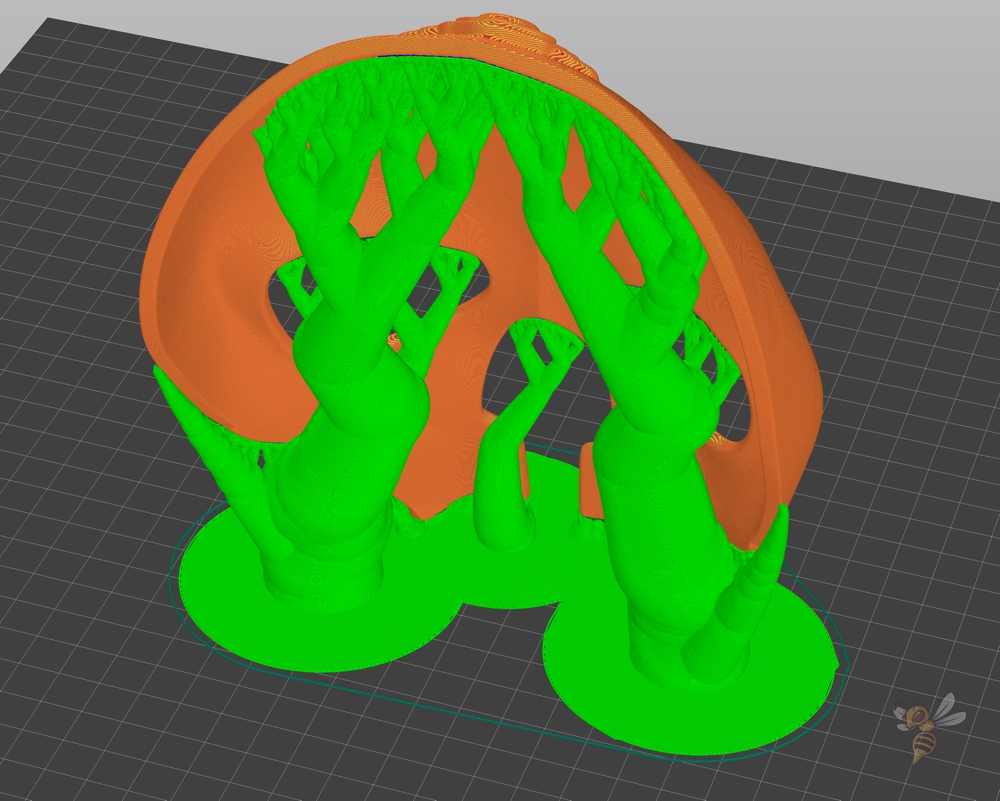

I hadn’t mentioned it yet but in order to avoid the “drooping” of the filament for this print. I changed the infill from 20% to 30% and changed the orientation in which the model is printed. An example is shown below.

Before

After

Once again thanks for tuning in. I had a great time with this project, and I think I learned a good bit. I think there is much more that can be done with this concept and there are plenty examples of “model molecules” that can be printed to be used as a teaching tool. I may continue this project in my own time before presenting to the Research and Creativity Day symposium in the Spring because there was more that I wished to do. My big idea for this project was to make a series of models that can explain mechanism of molecules such as hemoglobin, but I ran out of time. For example, imagine a series of models that starts with a model of hemoglobin similar to what I had done in this project but with a highlighted section (section printed in a different filament). Then next to this model was another model that is the same color as the highlighted section (for example the porphyrin rings) which shows how the interactions of the ring to hemoglobin allows interactions with oxygen or CO2. I had an idea to make a wider model stand that can occupy two models to be displayed which would facilitate this idea. Anyways, good luck to those who wish to replicate this process.