Transcript with Helpful Links

(Jaunty intro music)

Ally: Welcome to the Digital Creator Podcast, the show where we spotlight students working on cool digital projects. I’m Ally, a consultant at the Digital Knowledge Center where we empower students to be digital creators. Today’s guest took his love of playing the bagpipes to new levels by 3D printing practice chanters for the Eagle pipe band.

AJ: Hello, my name is AJ Gluchowski. I am a senior graduating in May of 2024, and I am a communication digital studies major. That has only been a thing for about two years. I’ve jumped around a whole lot. So, I’ve. I can say I have concentrations and different things, but that’s as much as I can say. I have been working on 3D printing bagpipes. For a while. It was just I came in here last fall and wanted to do something interesting, and I’ve been playing bagpipes for a long time and figured I could just make something out of that.

Ally: Yeah, that’s awesome. So how did you get into bagpipes? I feel like that’s not something you hear often. People playing that’s super unique. So, tell me a little bit about that.

AJ: Yeah. Yeah. So, I grew up in a musical family. I, like many other elementary schools, was offered a chance to play in the elementary school band. In 4th grade and we had the long list of instruments to pick from and my top three were percussion, saxophone, and flute or something, I think.

Ally: Classic choices.

AJ: Yeah, exactly. And I ended up playing trumpet, but I my dad had played trumpet when he was in high school, and I had. He handed me his trumpet. His, his trumpet. That was in shambles. And so, I played trumpet from 4th grade until the end of 8th grade, auditioned for my high school Marching Band on trumpet, and got in. And then I was like, hmm, I don’t love playing trumpet. But my high school Liberty High School in Bethlehem, PA, has a bagpipe band, and I never had really thought anything of it. I’d seen them like in parades, because in middle school I’d march with the high schools and my mom sat me down and. Was like, what about? Bagpipes instead of trumpet, and I was like. I don’t know what bagpipes are, and so after I finished eighth grade. The high schoolers that were in the bagpipe band started a program called Diaper Pipers.

Ally: Oh my goodness.

AJ: So, I was a diaper piper between my 8th grade, like the summer between 8th grade and 9th grade and that was how I got started with bagpipes.

Ally: Was that something that drew you to Mary Washington?

AJ: My college search consisted of me logging on Google. My mom also logging on Google us doing the same thing, searching up colleges on the East Coast of the United States that had it back. And that’s.

Ally: Wow, how many search results came up something, yeah.

AJ: Like 10 and that narrowed down my choice and almost every school that I toured had a bagpipe band. So, I was like, I knew that that was something that I was interested in, and it was one weekend in, like, February of 2020, before everything went crazy. My dad and I got in the car. And we did a road trip out to Western Pennsylvania and then down here. And I saw two schools in Pennsylvania and then came down to UMW, and we had reached out to the Pipe Band here ahead of time. And there was a guy who was a rising senior at the time who had spoke to the Pipe Band. He was a bagpiper who was a student, and he spoke to the band and was like, hey, can we have, like, this impromptu? Practice for this guy that’s coming down to like, check out the band. And so, he gave me a tour of the school on some like rainy Saturday and later that night. The band had gotten together just so they could show me what they do, so I was. Yeah, the Pipe Band was a very big reason for me come into you.

Ally: So, at what point did “I love playing the bagpipes. I’m here for playing the bagpipes” turn into “hey, what if I started 3D printing parts for a bagpipe”?

AJ: Yeah, I. I have a very close friend who I made through playing bagpipes at high school when the pandemic hit. He was like mildly interested in 3D printing, but he started a Go fund me for himself to get a 3D Printer so he could start printing masks for the hospital. Yeah, it was great and.

Ally: Oh, that’s lovely.

AJ: In his like off time, he would just like make random stuff with it. I was like oh and he would like give me some things. Like little fidget toys that he would. Like and that like very that. That was the very beginning of my interest in 3D printing and I didn’t really do anything with it until last fall when I was like, oh, the DKC has printers I forgot about that. So in September of last year, September of 2022, I. Walked in here, got 3D printer trained and printed a couple of things I found online and then I. Like, because you all teach tinkercad so I like messed around with tinkercad a little bit and then I was like I could do more with this. So I reached out to my friend who was further along in the 3D printing journey than I was. He recommended a 3D modeling like web-based software to me called on shape. And from then on, YouTube University was my best friend. Yeah, so I taught myself how to use that program and.

Ally: I love it.

AJ: And I was just kind of like, I should do something that would benefit more people than just me because I could just make, like, little fidget toys that I would like, look at my trinkets.

Ally: Right, yeah.

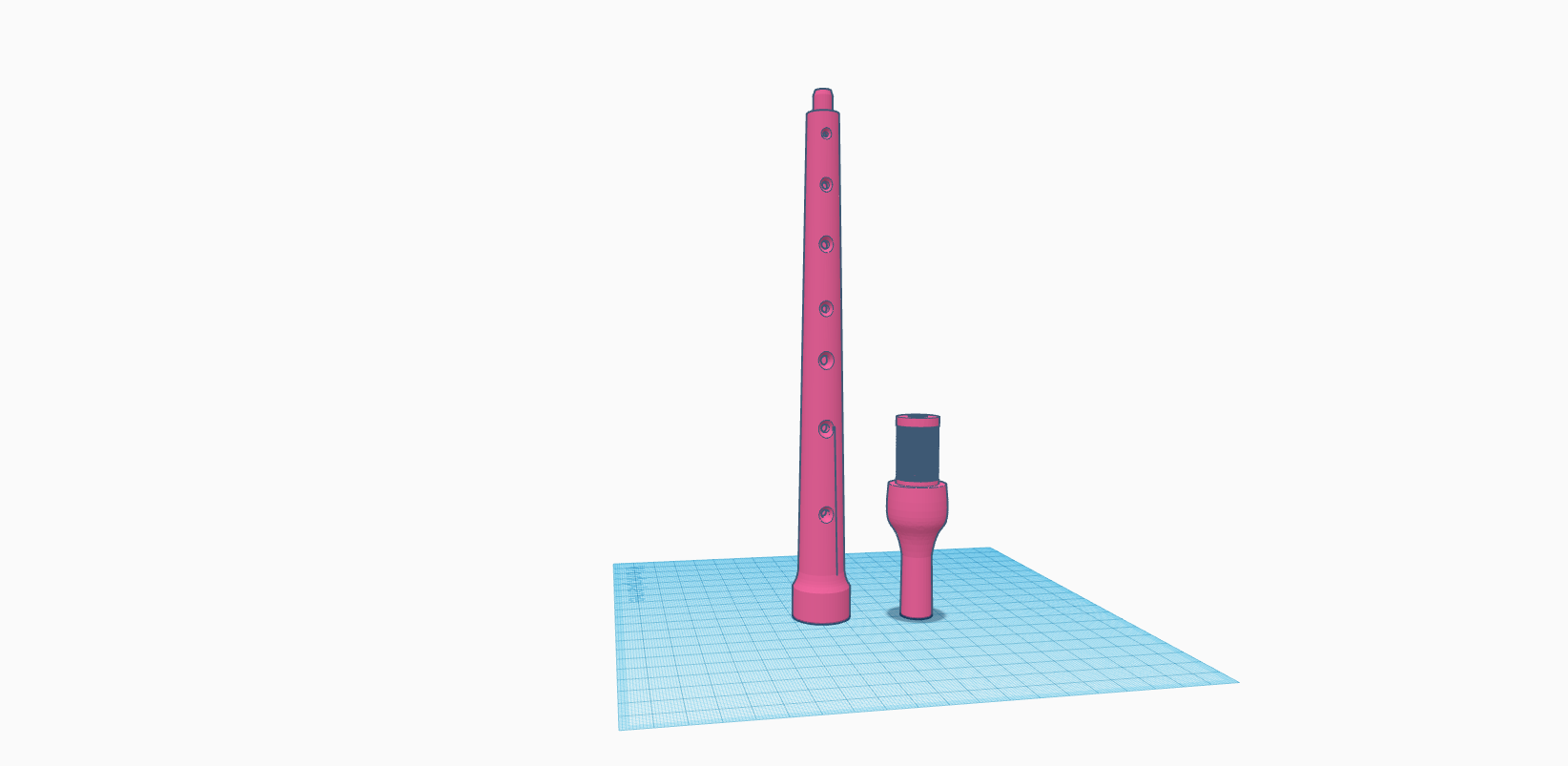

AJ: But I was like, I mean, I have other interests and. The instrument that you play. When you’re not playing, the full bagpipes is called a practice chanter, so it’s much smaller. And I was like I I that can’t be too hard to print. So, I talked to Cartland and Shannon about it, and Cartland had found a model online that someone had already made. So, we started. I started off printing that. And I wasn’t too satisfied with that. So then, like, started the whole process of me designing my own and things. Like that so.

Ally: For those who are like unfamiliar with the bagpipe, I feel like you think of it. It has those kind of more solid pieces than than like the bag, right? How much of the instrument itself are you designing in 3D printing and what kind of? Like is there like a different feel to certain parts that someone who’s been playing for as long as you have might know better than someone who you know just picks it up?

AJ: Yeah, yeah. So, I am not too far along on the actual bagpipes. I’ve printed one piece so far and have not been able to tell a difference. It might also change with repeated use, but we haven’t had too many practices since our last competition. But when it came to the practice chanter last year, I. Found no difference in either and I had committed to using the model that I had designed in October. I used from October until the end of December, and it was like no different. The sound quality was a little bit like more muted. But nothing noticeable and my goal was to give. All members of the Eagle Pipe Band, one of these chanters, so if they were to sound different at all, at least everybody would sound the same. But so far in the bagpipe world, what my plan is, is, I don’t think printing a bag is on the table.

Ally: A little more a. More difficult.

AJ: We’ve talked about it a little bit, yeah, but as for the like, solid pieces of the pipes, it comes down to the the actual pipes, the three pipes that like sit on your shoulder, there are 10 pieces total, I think. And a lot of them are just copy paste and like design one stretch it out, copy paste. So, like that whole process, I think I’ve taken for granted a little bit because it is going to be a little easy, but that’s still something I’m working toward figuring out.

Ally: Awesome! So, in any process there’s bound to be challenges. Do you have any specific moment where you just were really stuck at any point in your creative process with 3D printing the bag? Were you just like, hey, I don’t know what to do and you know. What did you do with that? How did you kind of move past that obstacle?

AJ: Yeah. So, I think there were a couple of instances, at least, toward the beginning of the project I remember trying to base the design that I like had made from scratch off of the one that Cartland and Shannon had found, and because our printers they’re normal sized printers but the the chanter that I was trying to make. Wasn’t going to fit. So what? The guy that we had found the chanter from, he had split it up into several different pieces. And then you, like, lock them together like Legos. And it worked. It just felt really flimsy and coming from high school. Playing bagpipes with 13 and 14 10 year olds, flimsy is not a good option because I just remember the sound of high schooler bagpipers flinging their chanters across the room, none of them breaking, and that’s what I wanted to go after, because the chanters that you can buy online are fairly.

Ally: No, no, no. Yeah, it’s good to have that durability, especially when you’re starting out, right.

AJ: Yes, yes. Yeah. Yeah. So, for the chanter that we found online, it just did not have that. And I just didn’t feel like that was what I wanted to get out of 3D printing chanters, like if it was something that I was going to give to everybody, I wanted it to be solid. So. First issue that I encountered aside from like. Not knowing printing techniques and like just prints failing in general. But the first issue I ran into when I started making my own chanter was it was too big to fail on the printer. How can I do that interlocking? How can I find another way to? Keep the chanter in one piece. So, what I ended up doing was and it. Was a very. Slow process. I printed the chanter straight up and down and had one little joint, so I had like the top of it, sitting next to the the the little like 2-inch-long top of it sitting next to like the 10-inch-long rest of it and had like that little Lego joint. And tested that quite a bit and it just was never durable like right at the joint. It would always snap. I got to a point where I was like, oh, this is probably gonna work and I would glue it, and I’d like use it for a couple of days and then I’d drop it on the ground one day and it’d snap immediately. Really. So that was one of the first issues and the way that we solved it, Cartland suggested that I design a couple of different joints just like based on how thick the walls were of like the receiving piece and how thick the like. Yeah, yeah, yeah, yeah. And so I designed five different joints, all with, like, different thicknesses to see what one would work, printed them all off and then use two pairs of pliers and tried to just. I snapped them all to see, like, which one would be most resistant. None of them. We’re great, but I then took that data and made a new one which lasted a little bit longer and I was like, alright, so I need to find a way to step away from the joint and reorient my print on the printer so that it could all be in one piece and I sacrificed a bit of like the aesthetic. It didn’t look as great, but I did get it to print in one piece at like a weird diagonal angle and was somewhat satisfied with that, and I turned my attention more toward the post processing and like sanding after it came off the printer to get it to look nicer because. Printing it in one piece definitely have the durability that I wanted.

Ally: Yeah, yeah, yeah. I feel like that’s a great example of a process really being a process and having to test things out and figure out what’s gonna work best for what you want out of your project. And it’s good to hear that durability was a focus of yours. That were able to kind of. Reach this place that you were happier with.

AJ: Yeah

Ally: for that product. So, this is kind of related, but I’ll I’ll let you decide if you want to go specific or general with this, but what is like one thing that you’ve learned in this process that has either informed future 3D printing projects or informed just how you go about a situation or other projects outside of 3D printing?

AJ: In regard to 3D printing, I’ve learned a lot about the process and paying attention to what you do before the file ever gets to the printer. Just what slicer you use, how you like prepare the print to go to the printer and settings and things like that. And I think that I now pay a lot more. Attention to that instead of. Just finding something online, throwing it on the printer and hoping for the best, which is what I did for the first couple of weeks of the last fall semester. But I think I have really found that I enjoy things like this, and I am majoring in communication and digital studies, so of the majors that UW offers. This kind of. encompasses, the DKC as a whole being digital, studies and all. But I am now looking toward a graduate program in digital media. And you know, I had been researching careers in 3D printing so profoundly, this has been something that has, you know, been a major interest to me for the past year, year and a half. And is something that I could see myself doing in the future.

Ally: Yeah, that’s awesome. I’m so happy to hear that. Do you find yourself? I know. Sometimes when I do a project, I’ll, like start noticing it in places outside of that workspace. Do you find yourself looking at instruments being like, oh, I wonder if that’s something I could do or like. Seeing how someone you know plays the bagpipes being like oh, maybe you know, having that inspire your work, seeing things outside of the workspaces that happen for you.

AJ: Yes, yes. So, toward the end of last fall. I just had the random. I had the random want to get a saxophone and so I reached out to one of my friends from high school and I was like, hey, you don’t players anymore, right? And he was like, yeah, you can have it. So, I borrowed it and brought it back after fall break, Thanksgiving break. And I had. To run around town trying to find a Reed because his Reed was moldy from high school. Yeah. And I was like, what if I 3D print this? And so, I spent a couple of hours trying to because it only took like 20-30 minutes to print, just ‘cause it was so thin trying to mess around with the settings and I used a lot of the knowledge that I had acquired from my chanter work. To make a saxophone reed and after a couple of iterations I got it to make sound. And I’m sure that there was more like post processing that went into it, but I headed home for winter break and didn’t really get to finish it off. But in regard to like other things out there, I have like now started since I’ve been 3D printing for so long, started to think about like random problems in my dorm room that could be solved with like a quick 3D print like. Oh no, I don’t have an extra command hook. Can I just go over to the DKC and print that real quick or like, oh, my hoodies don’t hang on my bed the way that I want them to. Like, can I rub the DKC in print something for that? So, like so I think now I don’t know if that’s like an engineering mindset of like, how can I solve this problem by creating something instead of. How can I solve this problem by like going to?

Ally: Buy something. Yeah, that’s great. I love hearing that. Like how that creativity translates throughout that. That’s great. What do you think has been most rewarding? For you in this process, is it the physical? Like I’m literally creating a physical product?

AJ: Yeah.

Ally: Or is it more than that? Obviously, it’s influenced how you see your life going forward. So, tell me a little bit more about that.

AJ: I think the creating something physical is a very big part of it of like I got satisfaction from printing the chanter that Cartland and Shannon had found at the beginning of last fall. And I was like, oh, that’s cool. Maybe this is what I just, like, engrave Eagle Pipe Band on and start giving it out to people. But I was. Like I’m not satisfied with that. And you know, I thought it would be 10 times cooler to hand people something I can say that I did from scratch. And so that realization of like I could put a little more work into this and find something that I’m like really proud of. I think that was a cool realization to have.

Ally: Yeah. So, you mentioned earlier that when you were thinking about going to 3D printing for this project that you just like. Came in here and asked about it. How did you hear about the 3D printers at the DKC?

AJ: Yeah, I was in here for 3D printing 3D printer training. My sophomore year, I believe when it was in the room next door, and I got training on the Dremel and just ran out of time and never came back. But I knew that they were here. I had heard about them the first time just from Flyers around campus and I think that one of my friends. Audra, who used to work at the DKC. She just graduated and she was always mentioning that there were 3D printers up here, so, you know, she was in the Eagle Pipe Band. She was a drummer. So just the connections around campus that you make, people know things. And I was like, ohh 3D printers in the DKC so. I think through people and through the copious amount of advertisements around campus.

Ally: Yes, you kind of mentioned looking into graduate programs, things like. That can you go into a little more depth about like to what capacity you want to kind of follow this love for 3D printing you know postgrad?

AJ: Yeah. So, like I said, I have fluctuated between like 20 different majors at this point and by 20, I mean like 4. But I came in a music major wanted to do computer science. After that I wanted to do philosophy. After that thought about like the sciences and then landed in communication and. Studies because it is that kind of broad degree. And I know that I struggle to settle with one thing ever in any respect and communication and digital studies has kind of opened that door for me to test out the things that I enjoy. I’m in a video production class right now. This past spring, I spent a lot of my free time. Trying to design a video game. From scratch I have been. I have logic on my MacBook, and I have been making music forever. All these like digital aspects in my life kind of can come together for like these digital studies classes at UW and then that’s what I want to go on and get a master’s degree in is I found a bunch of programs in digital media. I am looking at a program right now in Vancouver at the Centre for Digital Media, which is affiliated with Simon Fraser University, who has one of the best bagpipe bands in the world. So, I was. Like I should. Just go there.

Ally: When worlds collide.

AJ: Yes. So in regard to 3D printing, that’s now just a tool that I have in my toolbox and it’s something that I Will always you know if I have free time. I’ll go find a 3D printer and like either continue this bagpipe project or start a new project. And I’m sure that, you know, there will be opportunities in a digital Media Master’s program to continue with 3D printing. But even as just a hobby, I. Hopefully we’ll get a 3D printer at some point just to have.

Ally: Yeah, yeah. I think it’s interesting. I mean, if you really think about it, communications and digital digital studies is the perfect combination of music, philosophy, computer science, all of those things that you you tried out before. I feel like you’ve you’ve landed in a good spot. For what you’re looking to do, and that’s very exciting, but you’re able to find so many connections. Yeah, throughout the whole process.

AJ: Yes. Yeah.

Ally: Who knows? Maybe your friend will let you borrow there. That that thing that they Crowdsource like, hey, so just small thing. I’d have to move it across this country and then into another one. Do you think that like I can?

AJ: Yeah, that’d be great. Can I take it to Vancouver? Yeah. Can I fit it in a suitcase?

Ally: Check this at the airport. Will they flag this in security question mark?

AJ: Ohh gosh yeah, yeah.

Ally: All right. Good stuff. Thank you so much for coming in and talking with me today. I’ve, I’ve loved getting to know more about your process and what brought you here.

(outro music)

Ally: This has been the Digital Creator Podcast. You can find a transcript of our conversation and more below. This podcast was produced and edited by me, Ally Hamilton, with help from the resources at the Digital Knowledge Center. Are you interested in becoming a digital creator? Do you have a cool project you want to share? Go to dkc.umw.edu for information on how to get started! Thank you for listening!

(music continues)

For more information see AJ’s posts about his process.

Reply